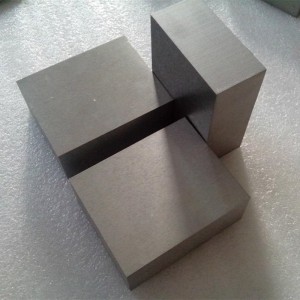

I-Silver Tungsten Alloy

I-Silver tungsten alloy yindibaniselwano engaqhelekanga yeentsimbi ezimbini ezimangalisayo, isilivere kunye ne-tungsten, enikezela ngeseti eyodwa yeepropathi kunye nokusetyenziswa.

I-alloy idibanisa i-conductivity yombane egqwesileyo yesilivere kunye nenqanaba eliphezulu lokunyibilika, ukuqina, kunye nokumelana nokunxiba kwe-tungsten. Oku kuyenza ifaneleke kakhulu kwizicelo ezahlukeneyo ezifuna ngamandla kwiindawo zombane nezoomatshini.

Kwishishini lombane, i-alloy ye-tungsten yesilivere isetyenziselwa ukunxibelelana kombane kunye nokutshintsha. Ikhono layo lokumelana nokushisa okuphezulu kunye ne-arcing yenza ukuba ithembeke kula macandelo abalulekileyo. Ngokomzekelo, kwiinkqubo zombane zamandla aphezulu, apho ukuhamba kwangoku kubaluleke kakhulu kwaye umngcipheko wokushisa uphezulu, ukusetyenziswa kwesilivere ye-tungsten alloy kuqinisekisa ukusebenza ngokufanelekileyo nokukhuselekileyo.

Kwindawo yomatshini, ifumana ukusetyenziswa kwezixhobo kwaye iyafa ngenxa yobunzima bayo kunye nokuqina. Amacandelo enziwe kule alloy anokumelana noxinzelelo olunzulu lomatshini kunye nokunxitywa kwe-abrasive, ukwandisa ubomi babo kunye nokuphucula ukusebenza.

Imveliso yesilivere ye-tungsten alloy ihlala ibandakanya iinkqubo ezinzima ukufezekisa ukubunjwa okufunwayo kunye ne-microstructure. Oku kuqinisekisa ibhalansi efanelekileyo yeepropati zezicelo ezithile.

Uphando kunye nophuhliso kwintsimi yesilivere ye-tungsten alloys iyaqhubeka nokuguquka, ivula amathuba amatsha kunye nokuphucula. Izazinzulu kunye neenjineli zihlala zijonga iindlela zokuphucula iipropathi zayo kunye nokwandisa uluhlu lwayo lwesicelo.

Ukuqukumbela, i-alloy yesilivere ye-tungsten ime njengobungqina bobuchule bomntu kwisayensi yezinto, inikezela ngezisombululo kwezinye zezona ngxaki zinzima zobunjineli kunye nezobuchwepheshe. Ukudityaniswa kwayo okukhethekileyo kweepropathi kuyenza ibe yimathiriyeli eyimfuneko kumashishini ahlukeneyo, ukubumba ihlabathi lanamhlanje kunye nobukho bayo kunye nobuchule.

Ukwenziwa kwesilivere ye-tungsten alloy:

I-Metallurgy yomgubo:

Le yindlela eqhelekileyo. Iipowders ezintle zesilivere kunye ne-tungsten zixutywe kwimilinganiselo efunwayo. Umxube ke uhlanganiswe phantsi koxinzelelo oluphezulu ukwenza i-compact eluhlaza. Le compact ithi emva koko itshiswe kubushushu obuphezulu ukuze idibanise amasuntswana kunye kwaye yenze ialloy eqinileyo. Umzekelo, kwezinye iimeko, umgubo unokucolwa kunye kuqala ukuqinisekisa umxube we-homogeneous.

Ukubekwa kweMichiza yoMphunga (CVD):

Kule ndlela, ii-precursors zegesi ezinesilivere kunye ne-tungsten zingeniswa kwigumbi lokuphendula. Ngaphantsi kweemeko ezithile zokushisa kunye noxinzelelo, i-precursors isabela kwaye ifake kwi-substrate ukwenza i-alloy layer. Obu buchule buvumela ulawulo oluchanekileyo lokubunjwa kwe-alloy kunye ne-microstructure.

Electroplating:

I-Silver tungsten alloy nayo inokwenziwa nge-electroplating. I-tungsten substrate intywiliselwa kwi-electrolyte equkethe i-ion zesilivere. Ngokusebenzisa umsinga wombane, isilivere ifakwe kwi-tungsten surface, yenza i-alloy layer. Le nkqubo inokulungelelaniswa ukufezekisa ubuninzi obuhlukeneyo kunye nokubunjwa kwe-alloy coating.

I-Sinter-HIP (I-Hot Isostatic Pressing):

Umxube womgubo uqala ukutshizwa kwaye emva koko uphantsi koxinzelelo olushushu lwe-isostatic. Oku kunceda ukuphelisa i-porosity kunye nokuphucula ukuxinana kunye neempawu zomatshini we-alloy eyenziwe.

Ukukhethwa kwendlela yokwenziwa kuxhomekeke kwizinto ezahlukeneyo ezifana neempawu ezifunwayo ze-alloy yokugqibela, imilo kunye nobukhulu becandelo eliza kuveliswa, kunye nomlinganiselo wemveliso. Indlela nganye ineengenelo kunye nemida yayo, kwaye amaxesha amaninzi, indibaniselwano yezi ndlela inokusetyenziswa ukufikelela ezona ziphumo zilungileyo.

I-Silver tungsten alloy inezicelo ezininzi ezithile ngenxa yeempawu zayo ezizodwa:

Abafowunelwa boMbane:

● Kwi-high-voltage circuit breakers, apho inokusingatha imisinga emikhulu kunye nokutshintsha rhoqo ngaphandle kokugqoka okubalulekileyo okanye ukuthotywa.

● Kwii-relays kunye nabafowunelwa kwiinkqubo zokulawula i-industrial, ukubonelela ngokuqhagamshelwa kombane okuthembekileyo kunye nobomi benkonzo ende.

Ii-electrodes:

● Ukukhutshwa kombane (EDM), apho i-conductivity yayo ephezulu kunye nokuchasana nokugqoka kuqinisekisa ukususwa kwezinto ezichanekileyo kunye nokusebenzayo.

● Kwi-arc welding electrodes, enikezela ngokuchithwa kakuhle kobushushu kunye nokuqina.

Izixhobo ze-Aerospace:

● Kwiindawo zeenjini zenqwelomoya kunye neenkqubo zesiphekepheke ezifuna imathiriyeli enokumelana nobushushu obuphezulu kunye namandla omatshini.

Ulawulo lweThermal:

● Njengoko ubushushu butshona kwizixhobo zombane, buqhuba ngokufanelekileyo kwaye bubukhuphe ubushushu.

Izixhobo kunye nokufa:

● Ukwenziwa kwestampu kunye nokwenza imisebenzi, ngakumbi kwizicelo apho ubunzima obuphezulu kunye nokumelana nokunxiba kubalulekile.

Ubucwebe:

● Ngenxa yembonakalo ekhangayo kunye nokuqina kwayo, ingasetyenziselwa ekudaleni iziqwenga zobucwebe obukhethekileyo.

Ngokomzekelo, kwishishini leemoto, unxibelelwano lwesilivere lwe-tungsten alloy lusetyenziswa kwiimotor zokuqalisa ukuqinisekisa ukuqala okuthembekileyo kwe-injini phantsi kweemeko ezahlukeneyo. Kwintsimi yezonxibelelwano, iqeshwe kwiinguqu eziphezulu ze-frequency ukuze kugcinwe ingqibelelo yesignali kunye nokunciphisa ilahleko yesignali.

Iipropati zeSilver Tungsten Alloy

| Inombolo yekhowudi. | Ukuqulunqwa kwemichiza % | Iimpawu zoomatshini | ||||||

| Ag | Ukungcola≤ | W | Ukuxinana (g/cm3 ) ≥ | Ukuqina HB ≥ | I-RES (μΩ·cm) ≤ | Ukuqhuba IACS/ % ≥ | TRS/ Mpa ≥ | |

| AgW(30) | 70±1.5 | 0.5 | Ibhalansi | 11.75 | 75 | 2.3 | 75 | |

| AgW(40) | 60±1.5 | 0.5 | Ibhalansi | 12.40 | 85 | 2.6 | 66 | |

| AgW(50) | 50±1.5 | 0.5 | Ibhalansi | 13.15 | 105 | 3.0 | 57 | |

| AgW(55) | 45±2.0 | 0.5 | Ibhalansi | 13.55 | 115 | 3.2 | 54 | |

| AgW(60) | 40±2.0 | 0.5 | Ibhalansi | 14.00 | 125 | 3.4 | 51 | |

| AgW(65) | 35±2.0 | 0.5 | Ibhalansi | 14.50 | 135 | 3.6 | 48 | |

| AgW(70) | 30±2.0 | 0.5 | Ibhalansi | 14.90 | 150 | 3.8 | 45 | 657 |

| AgW(75) | 25±2.0 | 0.5 | Ibhalansi | 15.40 | 165 | 4.2 | 41 | 686 |

| AgW(80) | 20±2.0 | 0.5 | Ibhalansi | 16.10 | 180 | 4.6 | 37 | 726 |