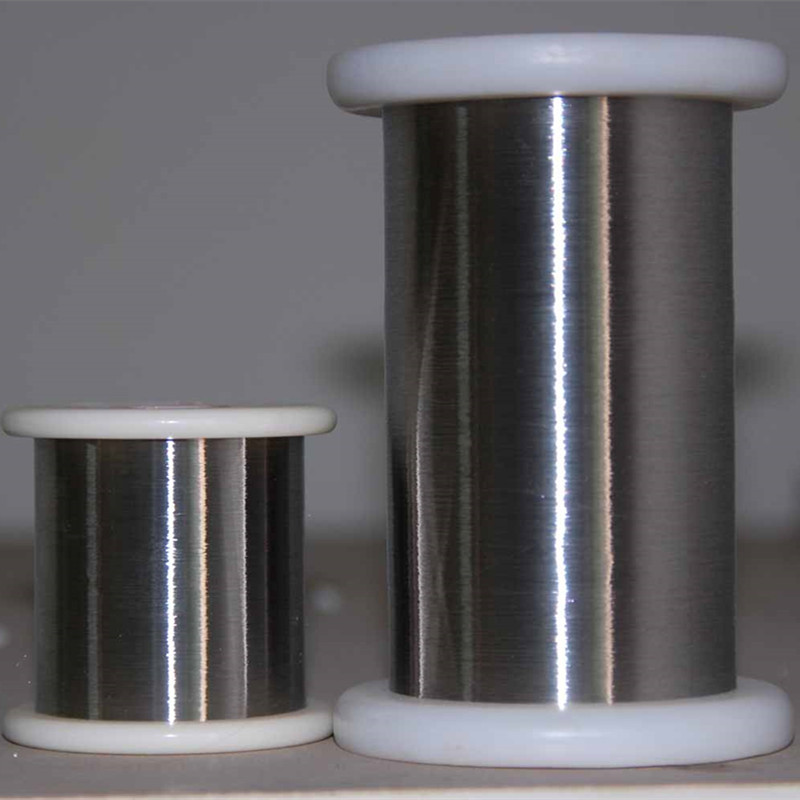

I-Nickel Chromium NiCr iAloy Wire

I-0.03mm yocingo lwe-NiCr Alloy, 637 MPA iNickel Chromium Wire Heating, Ni90Cr10 NiCr Alloy

I-Ni90Cr10 yi-austenitic nickel-chromium alloy efanelekileyo kwizicelo zobushushu ukuya kwi-1250°C. Umxholo ophezulu we-chromium (i-30% kwi-avareji) inika ixesha elihle kakhulu lobomi, ngokukodwa kwizicelo zesithando somlilo, isetyenziswa kakhulu kwi-vape, njengento yokufudumeza.

I-Ni90Cr10 ibonakaliswe ngokuxhathisa okuphezulu, ukuxhathisa okulungileyo kwe-oxidation, i-ductility efanelekileyo emva kokusetyenziswa kunye ne-weldability egqwesileyo. I-alloy ayikho phantsi "kokubola okuluhlaza" kwaye ifaneleke ngokukodwa ekunciphiseni kunye ne-oxidizing atmospheres.

I-Ni70Cr30 isetyenziselwa izinto zokufudumeza zombane kwiziko lamashishini. Ukusetyenziswa okuqhelekileyo zezi: iziko zombane kunye ne-enamelling, izifudumezi zokugcina, iziko kunye neekilni ezinomoya oguqukayo.

Usetyenziso lweeNcingo ze-NiCr Alloy:

Izinto ze-nickel-chromium zinamandla aphezulu okushisa kunye neplastiki eqinile.

Isetyenziswa kakhulu kwiziko lombane kwimizi-mveliso, izixhobo zasekhaya, izixhobo ezikude ze-infrared.

I-Nickel-chromium kunye nentsimbi, i-aluminium, i-silicon, i-carbon, isulfure kunye nezinye izinto zingenziwa kwi-alloy nickel-chromium wire kunye nokumelana okuphezulu kunye nokuxhathisa ukushisa. Yinto yokufudumeza kombane yesitovu sombane, intsimbi yokuthambisa yombane, intsimbi yombane, njl.

Izinto eziluncedo zeNickel-Chromium Wire:

Ukuxhathisa kuphezulu kakhulu, umaleko womphezulu unokumelana ne-oxidation elungileyo, kwaye amandla oxinzelelo agcinwa ngcono kunocingo lwe-iron-chromium-aluminium phantsi kobushushu obuphezulu bendalo, kwaye ukusebenza kobushushu obuphezulu akukho lula ukuvelisa i-deformation. Ucingo lwe-nickel-chromium lune-deformation yeplastiki efanelekileyo, iimpawu ezintle kakhulu zokucwangcisa kunye nokukwazi ukubumba, kulula ukuvelisa kunye nokusebenza, kulula ukulungisa kwaye kunzima ukutshintsha kwisakhiwo. Ukongeza, ucingo lwe-nickel-chromium lunokukhutshwa okuphezulu, ukuxhathisa okuhle kokubola kunye nexesha elide lokusebenzisa.

Iitafile ze-nickel-chromium alloy performance

| Izinto zokusebenza | Cr10Ni90 | Cr20Ni80 | Cr30Ni70 | Cr15Ni60 | Cr20Ni35 | Cr20Ni30 | |

| Ukuqamba | Ni | 90 | Phumla | Phumla | 55.0-61.0 | 34.0-37.0 | 30.0-34.0 |

| Cr | 10 | 20.0-23.0 | 28.0-31.0 | 15.0-18.0 | 18.0-21.0 | 18.0-21.0 | |

| Fe |

| ≤1.0 | ≤1.0 | Phumla | Phumla | Phumla | |

| Elona qondo lobushushu℃ | 1300 | 1200 | 1250 | 1150 | 1100 | 1100 | |

| Indawo yokunyibilika ℃ | 1400 | 1400 | 1380 | 1390 | 1390 | 1390 | |

| Ubuninzi be-g/cm3 | 8.7 | 8.4 | 8.1 | 8.2 | 7.9 | 7.9 | |

| Ukuxhathisa |

| 1.09±0.05 | 1.18±0.05 | 1.12±0.05 | 1.00±0.05 | 1.04±0.05 | |

| μΩ·m,20℃ | |||||||

| Ubude ekugqabhukeni | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | |

| Ubushushu obuthile |

| 0.44 | 0.461 | 0.494 | 0.5 | 0.5 | |

| J/g.℃ | |||||||

| I-Thermal conductivity |

| 60.3 | 45.2 | 45.2 | 43.8 | 43.8 | |

| KJ/mh℃ | |||||||

| I-Coefficient yokwandiswa kwemigca |

| 18 | 17 | 17 | 19 | 19 | |

| a×10-6/ | |||||||

| (20~1000℃) | |||||||

| Ubume beMicrographic |

| Austenite | Austenite | Austenite | Austenite | Austenite | |

| Iimpawu zemagneti |

| Nonmagnetic | Nonmagnetic | Nonmagnetic | Imagnethi ebuthathaka | Imagnethi ebuthathaka | |