I-Tungsten Copper WCu iSinki yoBubushushu

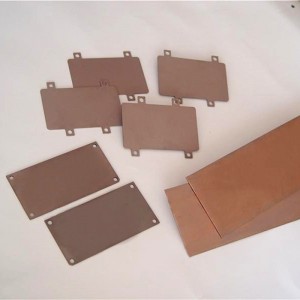

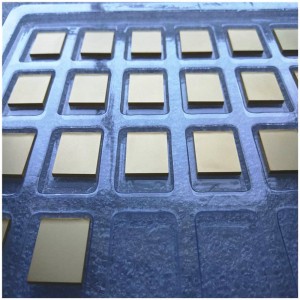

Inkcazo

Izinto zokupakisha ze-elektroniki ze-Tungsten zobhedu zineepropathi ezisezantsi zokwandiswa kwe-tungsten kunye neempawu eziphezulu ze-thermal conductivity yobhedu. Eyona nto ibaluleke kakhulu kukuba i-coefficient yayo yokwandisa i-thermal kunye ne-thermal conductivity inokuqulunqwa ngokuhlengahlengisa ukubunjwa kwezinto ezizisa ukukhululeka okukhulu.

I-FOTMA isebenzisa ubunyulu obuphezulu kunye nomgangatho ophezulu wezinto eziluhlaza, kwaye ifumana izinto zokupakisha ze-WCu ze-elektroniki kunye nezixhobo zokutshiza ubushushu kunye nokusebenza okugqwesileyo emva koxinzelelo, ubushushu obuphezulu kunye nokungena ngaphakathi.

Izinto eziluncedo zeTungsten Copper (WCu) i-Electronic Packaging Materials

1. I-tungsten yethusi ye-electronic packaging material ine-coefficient yokwandiswa kwe-thermal adjustable, enokuthi ihambelane ne-substrates eyahlukeneyo (njenge: insimbi engenasici, i-valve alloy, i-silicon, i-gallium arsenide, i-gallium nitride, i-aluminium oxide, njl.);

2. Akukho zixhobo zokuvula i-sintering zongezwa ukuze kugcinwe ukuhanjiswa kakuhle kwe-thermal;

3. I-porosity ephantsi kunye nokuqina kakuhle komoya;

4. Ukulawula ubungakanani obuhle, ukugqiba umphezulu kunye nokukhanya.

5. Ukubonelela ngephepha, iindawo ezenziweyo, nazo zinokuhlangabezana neemfuno ze-electroplating.

IiPropathi zeSinki yeTungsten yoHeat

| IBanga leMathiriyeli | Umxholo weTungsten Wt% | Ubuninzi be-g/cm3 | Ukwandiswa kweThermal × 10-6CTE (20℃) | I-Thermal Conductivity W/ (M·K) |

| 90WCu | 90±2% | 17.0 | 6.5 | 180 (25℃) /176 (100℃) |

| 85WCu | 85±2% | 16.4 | 7.2 | 190 (25℃)/ 183 (100℃) |

| 80WCu | 80±2% | 15.65 | 8.3 | 200 (25℃) / 197 (100℃) |

| 75WCu | 75±2% | 14.9 | 9.0 | 230 (25℃) / 220 (100℃) |

| 50WCu | 50±2% | 12.2 | 12.5 | 340 (25℃) / 310 (100℃) |

Ukusetyenziswa kweTungsten Copper Heat sinks

Izinto ezilungele ukupakishwa ngezixhobo eziphezulu zamandla, ezifana ne-substrates, i-electrodes ephantsi, njl.; iifreyimu zokukhokela ezisebenza kakhulu; iibhodi zolawulo lwe-thermal kunye neeradiyetha zomkhosi kunye nezixhobo zokulawula ubushushu boluntu.