Ujoliso lweTungsten Sputtering

Ujoliso lweTungsten Sputtering

Iithagethi ze-Tungsten zokutshiza zidlala indima ebalulekileyo kwiinkqubo ezahlukeneyo zetekhnoloji zanamhlanje. Ezi thagethi ziyinxalenye ebalulekileyo yenkqubo ye-sputtering, esetyenziswa ngokubanzi kumashishini afana ne-electronics, i-semiconductors, kunye ne-optics.

Iipropathi ze-tungsten zenza kube lukhetho olufanelekileyo kwiithagethi ze-sputtering. I-Tungsten yaziwa ngendawo yayo ephezulu yokunyibilika, i-thermal conductivity egqwesileyo, kunye noxinzelelo lomphunga ophantsi. Ezi mpawu zivumela ukuba zimelane nokushisa okuphezulu kunye ne-bhombardment yamasuntswana anamandla ngexesha lenkqubo yokutshiza ngaphandle kokuthotywa okukhulu.

Kwishishini le-elektroniki, iithagethi ze-tungsten sputtering zisetyenziselwa ukufaka iifilimu ezibhityileyo kwii-substrates zokwenziwa kweesekethe ezidibeneyo kunye nezixhobo ze-microelectronic. Ulawulo oluchanekileyo lwenkqubo ye-sputtering luqinisekisa ukufana kunye nomgangatho weefilimu ezigciniweyo, ezibaluleke kakhulu ekusebenzeni kunye nokuthembeka kwamacandelo e-elektroniki.

Ngokomzekelo, kwimveliso ye-flat-panel displays, iifilimu ze-tungsten ezincinci ezifakwe kusetyenziswa iithagethi ze-sputtering zifaka isandla ekusebenzeni kunye nokusebenza kweepaneli zokubonisa.

Kwicandelo le-semiconductor, i-tungsten isetyenziselwa ukudala i-interconnects kunye ne-barrier layers. Ukukwazi ukufaka iifilimu ze-tungsten ezincinci kunye ne-conformal zinceda ekunciphiseni ukuxhathisa kombane kunye nokuphucula ukusebenza kwesixhobo ngokubanzi.

Izicelo ze-Optical nazo zizuza kwiithagethi ze-tungsten sputtering. Iingubo zeTungsten zinokuphucula ukubonakaliswa kunye nokuqina kwezinto ezibonakalayo, ezifana nezibuko kunye neelensi.

Umgangatho kunye nokucoceka kweethagethi ze-tungsten sputtering kubaluleke kakhulu. Nokuba ukungcola okuncinci kunokuchaphazela iipropati kunye nokusebenza kweefilimu ezigciniweyo. Abavelisi basebenzisa imilinganiselo engqongqo yolawulo lomgangatho ukuqinisekisa ukuba usukelo luyahlangabezana neemfuno ezibangwayo zezicelo ezahlukeneyo.

Iithagethi ze-Tungsten sputtering zibalulekile ekuqhubeleni phambili kwetekhnoloji yale mihla, ivumela ukuyilwa kweefilimu ezikumgangatho ophezulu ezithi ziqhube uphuhliso lwe-elektroniki, i-semiconductors, kunye ne-optics. Uphuculo lwabo oluqhubekayo kunye nokuveliswa kwezinto ezintsha ngokungathandabuzekiyo kuya kudlala indima ebalulekileyo ekubumbeni ikamva lala mashishini.

Iindidi ezahlukeneyo zeethagethi zeTungsten Sputtering kunye nezicelo zazo

Kukho iintlobo ezininzi zeethagethi ze-tungsten sputtering, nganye ineempawu zayo kunye nokusetyenziswa kwayo.

Iithagethi zeTungsten ezicocekileyo zokutshiza: Ezi zenziwe nge-tungsten ecocekileyo kwaye zihlala zisetyenziselwa izicelo apho indawo ephezulu yokunyibilika, i-conductivity egqwesileyo ye-thermal, kunye noxinzelelo oluphantsi lomphunga luyimfuneko. Ngokuqhelekileyo baqeshwe kwishishini le-semiconductor ngokufaka iifilimu ze-tungsten zokudibanisa kunye neengqimba zomqobo. Ngokomzekelo, ekwenzeni i-microprocessors, i-tungsten sputtering ecocekileyo inceda ukudala unxibelelwano oluthembekileyo lombane.

Iithagethi eziDityanisiweyo zeTungsten zokutshiza: Ezi thagethi ziqulethe i-tungsten edityaniswe nezinye izinto ezifana ne-nickel, i-cobalt, okanye i-chromium. Iithagethi ze-tungsten ezidibeneyo zisetyenziselwa xa iipropati eziphathekayo ezifunekayo. Umzekelo ukwishishini le-aerospace, apho i-alloyed tungsten sputtering target isenokuthi isetyenziswe ukwenza ii-coatings kumalungu einjini yomoya ukomeleza ukumelana nobushushu kunye nokungagugi.

Iithagethi zeTungsten Oxide zokuSputtering: Ezi zisetyenziswa kwizicelo apho iifilimu ze-oxide zifuneka. Bafumana ukusetyenziswa kwimveliso ye-transparent conductive oxides kwiziboniso zesikrini esichukumisayo kunye neeseli zelanga. Uluhlu lwe-oxide lunceda ekuphuculeni ukuqhutyelwa kombane kunye neempawu ze-optical zemveliso yokugqibela.

Iithagethi zeTungsten zokuSputtering ezihlanganisiweyo: Ezi ziquka i-tungsten edibeneyo kunye nezinye izinto kwisakhiwo esidibeneyo. Zisetyenziswa kwiimeko apho indibaniselwano yeepropathi ezivela kumacandelo omabini zifunwa. Ngokomzekelo, ekufakweni kwezixhobo zonyango, i-tungsten edibeneyo ekujoliswe kuyo ingasetyenziselwa ukudala i-biocompatible kunye neyokuhlala ixesha elide.

Ukukhethwa kohlobo lwethagethi ye-tungsten ye-sputtering kuxhomekeke kwiimfuno ezithile zesicelo, kubandakanywa neempawu zefilimu ezifunwayo, izinto ze-substrate, kunye neemeko zokucubungula.

Isicelo sokuJonga iTungsten

Isetyenziswe ngokubanzi kwimiboniso yeepaneli ezicaba, iiseli zelanga, iisekethe ezidibeneyo, iglasi yemoto, i-microelectronics, imemori, iityhubhu ze-X-ray, izixhobo zonyango, izixhobo zokunyibilika kunye nezinye iimveliso.

Ubungakanani beThagethi yeTungsten:

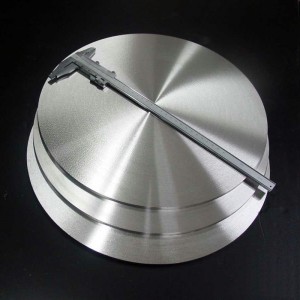

Idiski ekujoliswe kuyo:

Ububanzi: 10mm ukuya 360mm

Ukutyeba: 1mm ukuya 10mm

Ithagethi ecwangcisiweyo

Ububanzi: 20mm ukuya 600mm

Ubude: 20mm ukuya 2000mm

Ukutyeba: 1mm ukuya 10mm

Ithagethi yeRotary

Idayamitha yangaphandle: 20mm ukuya kuma-400mm

Ubunzima bodonga: 1mm ukuya kwi-30mm

Ubude: 100mm ukuya 3000mm

IiNgcaciso zeThagethi yeTungsten Sputtering:

Imbonakalo: isilivere emhlophe yentsimbi

Ubunyulu: W≥99.95%

Ubuninzi: ngaphezu kwe-19.1g/cm3

Imeko yobonelelo: Ukupholishwa komphezulu, ukusetyenzwa komatshini weCNC

Umgangatho womgangatho: ASTM B760-86, GB 3875-83