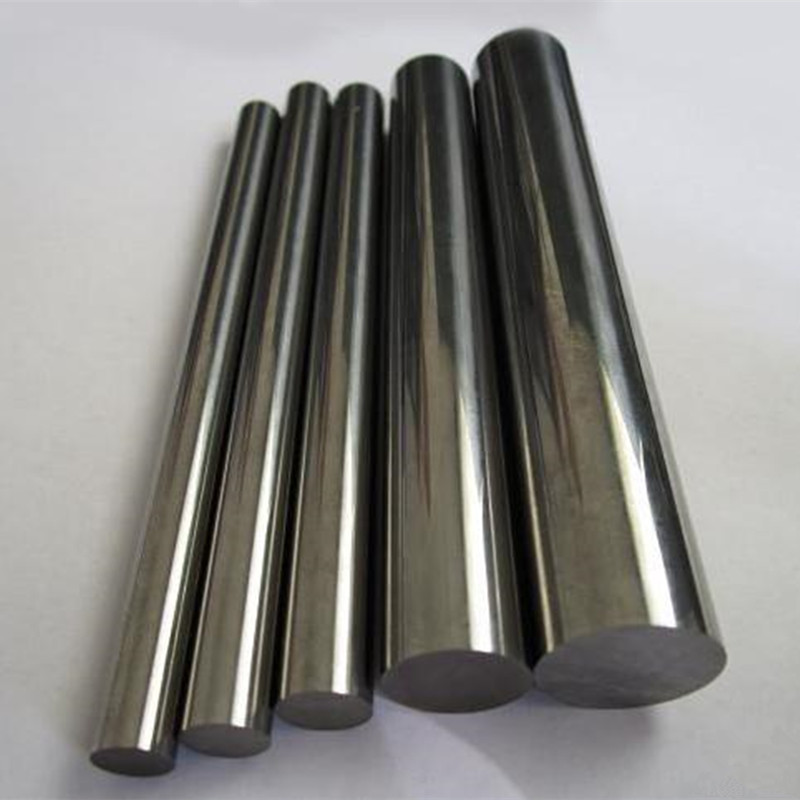

I-Tungsten Heavy Alloy Rod

Iinkcukacha

IBanga le-Tungsten Heavy Alloy:

W90NiFe/W92.5NiFe/W93NiFe/W95NiFe/W97NiFe (Imagnethi kancinane).

W90NiCu/W92.5NiCu/W93NiCu/W95NiCu/W97NiCu (Nonmagnetic).

Ubuninzi:16.8-18.8g/cm3.

Umphezulu:Okwenziweyo kunye noMhlaba.

Umgangatho:I-ASTM B777.

Ububanzi:5.0mm – 80mm.

Ubude:50mm - 350mm.

I-Tungsten High Density Alloy Advantages

Uxinaniso oluphezulu (ukuya kuthi ga kwi-65% denser kuneLead).

Izinto ezixineneyo zikhona (i-Tungsten ecocekileyo, iGolide, isinyithi seqela leplatinam) kodwa ukusetyenziswa kwazo kuthintelwe ngokufumaneka, ukusebenza kunye neendleko.

Ukubonelela ngobunzima apho isithuba somthamo silinganiselwe.

Ubunzima obugxininisiweyo buyimfuneko apho ukuchaneka kuyadingeka ekubekweni kobunzima.

Ukubekwa kobunzima kwiimeko apho ukuhamba komoya kunempembelelo enkulu.

IiPropati zeThermal zeTungsten Heavy Alloys

Ubushushu obuphezulu bokuthambisa.

I-conductivity ephantsi ye-thermal kunye ne-coefficient ephantsi yokwandisa inika izinto eziphathekayo ukuchasana nokudinwa kwe-thermal.

Ukumelana nokukhukuliseka okugqwesileyo kwi-aluminiyam etyhidiweyo.Unamandla kumaqondo aphezulu kunye nokuzinza okuphezulu kwe-thermal.

IiPropati zeMechanical zeMechanical ye-Tungsten High Density Alloy Mechanical

● High Young's imodyuli yokunwebeka.Ayichwechwe xa ifumana amandla abalulekileyo, ngokungafaniyo nelothe.

● Nangona zinamandla, zihlala zi-ductile kwaye zixhathisa ukuqhekeka.

● Uluhlu lobunzima bee-alloys ngokuqhelekileyo luyi-20-35 Hardness HRC.

Uxinaniso oluPhezulu oluSekwe kwingxubevange yeTungsten

| Uhlobo lwe-alloy(%) | I-HD17 90W 6Ni 4Cu | I-HD17D 90W 7Ni 3Fe | HD17.5 92.5W 5.25Ni 2.25Fe | HD17.6 92.5W Ibhalansi Ni, Fe, Mo | I-HD17.7 93W Ibhalansi Ni, Fe, Mo | I-HD18 95W 3.5Ni 1.5Cu | I-HD18D 95W 3.5Ni 1.5Fe | HD18.5 97W 2.1Ni .9Fe |

| I-MIL-T-21014 | Iklasi yoku-1 | Iklasi yoku-1 | Iklasi yoku-1 | - | - | Iklasi yesi-3 | Iklasi yesi-3 | Iklasi yesi-4 |

| I-SAE-AMS-T-21014 | Iklasi yoku-1 | Iklasi yoku-1 | Iklasi yesi-2 | - | - | Iklasi yesi-3 | Iklasi yesi-3 | Iklasi yesi-4 |

| I-AMS 7725 C | 7725 C | 7725 C | -- | -- | -- | -- | -- | -- |

| I-ASTM B777-87 | Iklasi yoku-1 | Iklasi yoku-1 | Iklasi yesi-2 | - | - | Iklasi yesi-3 | Iklasi yesi-3 | Iklasi yesi-4 |

| Uxinaniso oluqhelekileyo(g/cc) | 17.1 | 17.1 | 17.5 | 17.6 | 17.7 | 18 | 18 | 18.5 |

| Uxinaniso oluqhelekileyo(lbs/in3) | 0.614 | 0.614 | 0.632 | 0.636 | 0.639 | 0.65 | 0.65 | 0.668 |

| Ubulukhuni obuqhelekileyo RC | 24 | 25 | 26 | 30 | 32 | 27 | 27 | 28 |

| Ukomelela okuGqibeleleyo kokuqina(ksi) | 110,000 | 120,000 | 114,000 | 120,000 | 125,000 | 110,000 | 120,000 | 123,000 |

| 0.2% i-Offset Yield Strength Min(ksi) | 80,000 | 88,000 | 84,000 | 90,000 | 95,000 | 85,000 | 90,000 | 85,000 |

| Ubuncinci % Ubude(1" ubude begeyi) | 6 | 10 | 7 | 4 | 4 | 7 | 7 | 5 |

| Umlinganiselo we-Proportional Elastic(PSI) | 45,000 | 52,000 | 46,000 | 55,000 | 60,000 | 45,000 | 44,000 | 45,000 |

| Imodyuli yeElasticity(x106psi) | 40 x 106 | 45 x 106 | 47 x 106 | 52 x 106 | 53 x 106 | 45 x 106 | 50 x 106 | 53 x 106 |

| I-Coefficient yoKwandiswa kweThermal x10-6/0C(20-400C) | 5.4 | 4.61 | 4.62 | 4.5 | 4.5 | 4.43 | 4.6 | 4.5 |

| I-Thermal Conductivity(Iiyunithi zeCGS) | 0.23 | 0.18 | 0.2 | 0.27 | 0.27 | 0.33 | 0.26 | 0.3 |

| Ukuqhuba koMbane(% IACS) | 14 | 10 | 13 | 14 | 14 | 16 | 13 | 17 |

| Imagnethi | No | Kancinci | Kancinci | Kancinci | Kancinci | No | Kancinci | Kancinci |